What OctaPulse users actually want

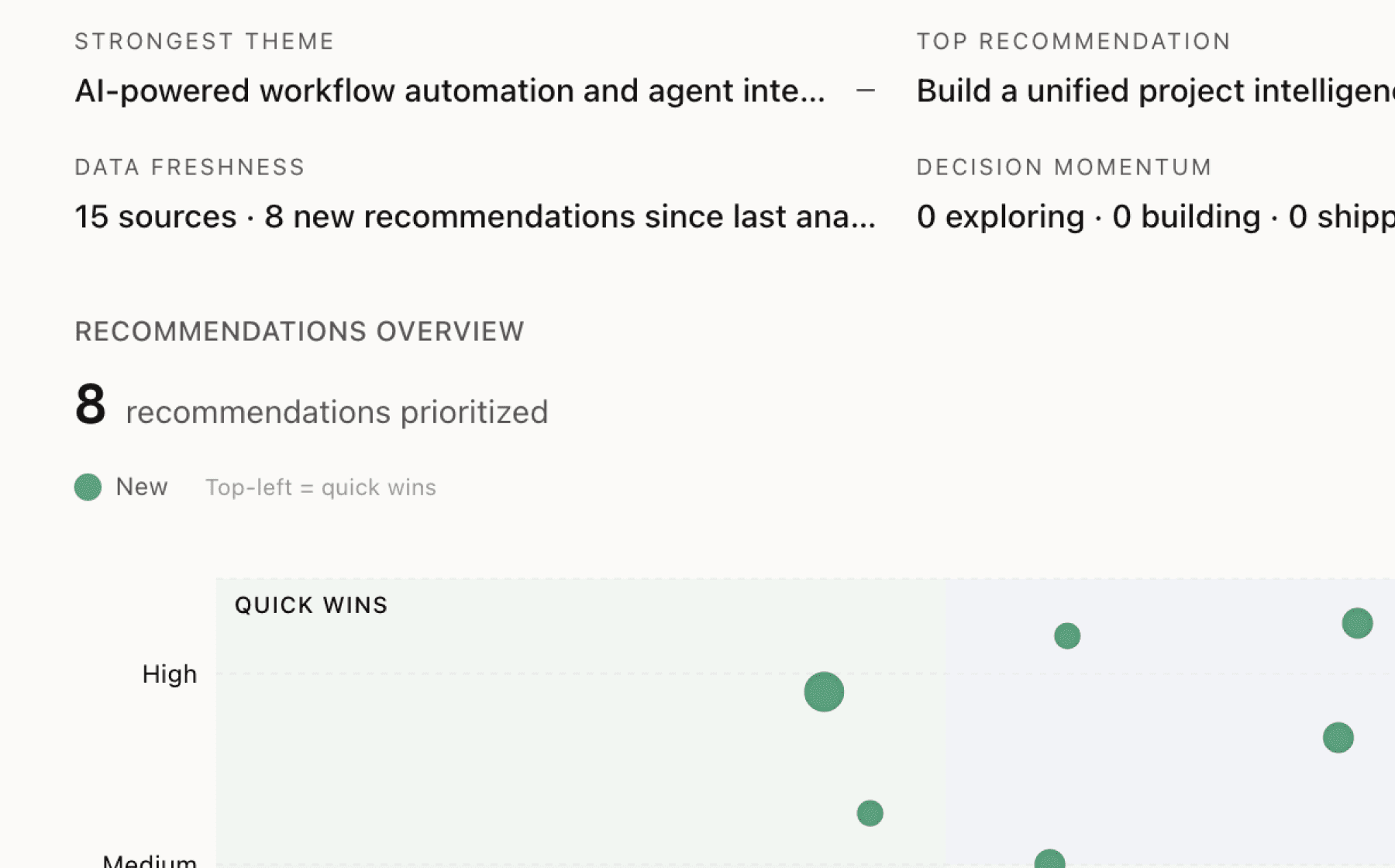

Mimir analyzed 9 public sources — app reviews, Reddit threads, forum posts — and surfaced 14 patterns with 7 actionable recommendations.

This is a preview. Mimir does this with your customer interviews, support tickets, and analytics in under 60 seconds.

Top recommendation

AI-generated, ranked by impact and evidence strength

Develop enterprise SLA package with guaranteed uptime and support commitments

High impact · Medium effort

Rationale

The data reveals a structural mismatch between product positioning and delivery guarantees. OctaPulse's automation runs 24/7 in production environments where downtime directly impacts live fish welfare and farm economics, yet terms of service offer no uptime guarantees and reserve immediate termination rights without notice. This creates adoption friction with enterprise customers who require mission-critical reliability.

Manual inspection is slow and inconsistent, which drives farms toward automation. But replacing manual processes with automated systems that lack reliability guarantees introduces new operational risk. Production customers need contractual confidence before committing to automation that handles live inventory.

An enterprise tier with 99.5% uptime SLA, dedicated support, and advance notice provisions would align service commitments with the production-critical nature of the platform. This directly supports user retention by reducing perceived risk and demonstrates maturity expected of infrastructure providers in food production.

Projected impact

The full product behind this analysis

Mimir doesn't just analyze — it's a complete product management workflow from feedback to shipped feature.

Evidence-backed insights

Every insight traces back to real customer signals. No hunches, no guesses.

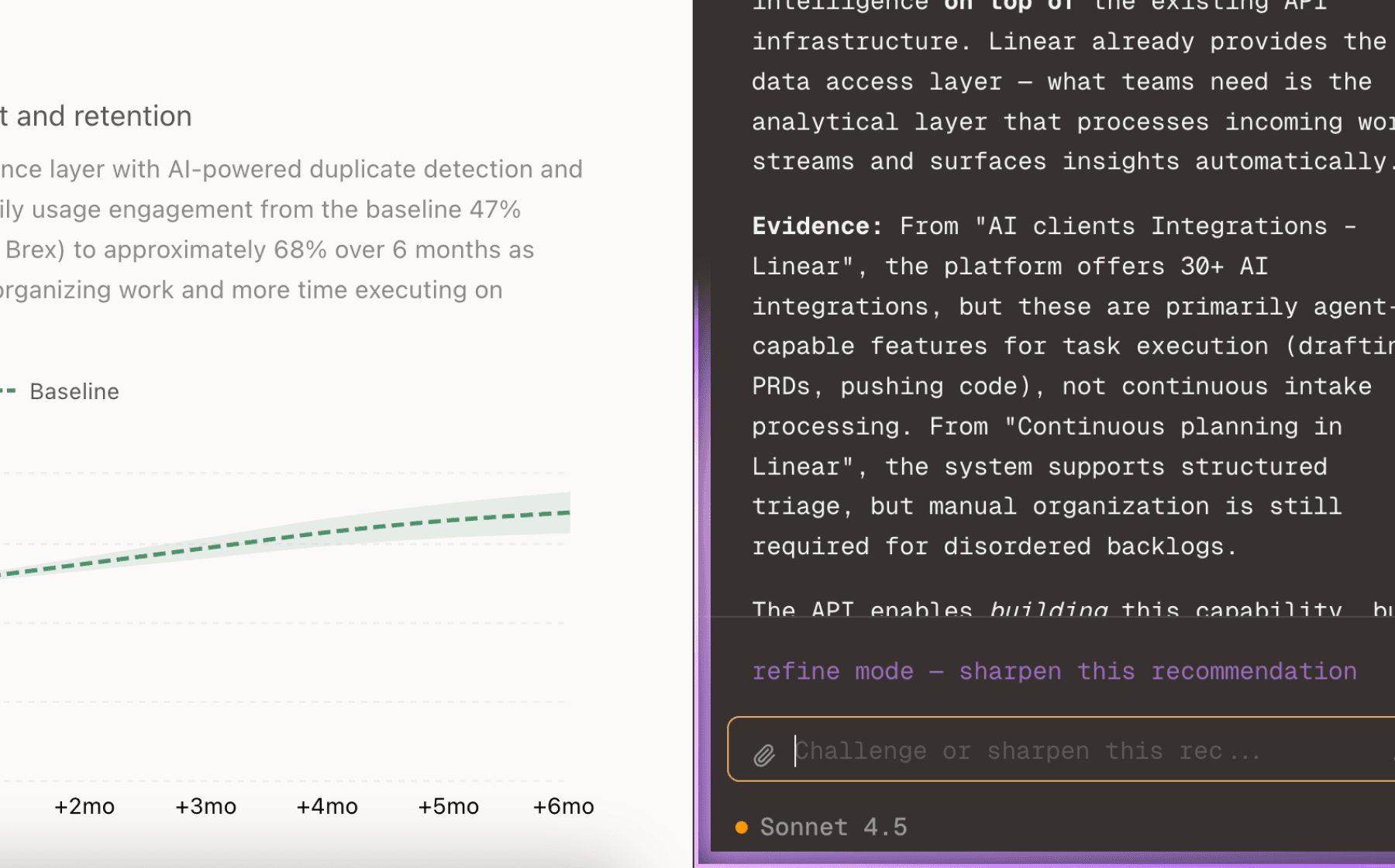

Chat with your data

Ask follow-up questions, refine recommendations, and capture business context through natural conversation.

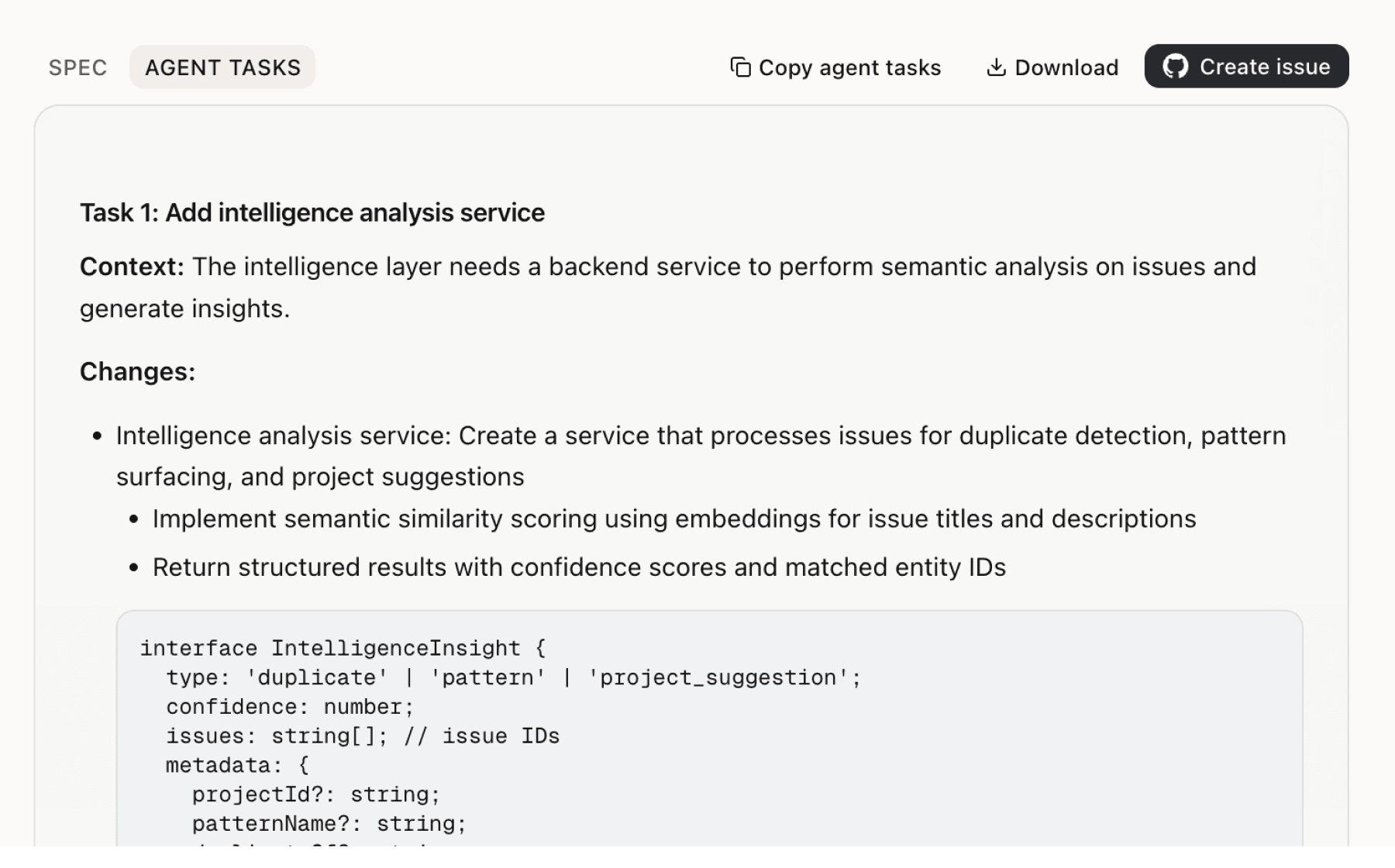

Specs your agents can ship

Go from insight to implementation spec to code-ready tasks in one click.

This analysis used public data only. Imagine what Mimir finds with your customer interviews and product analytics.

Try with your dataMore recommendations

6 additional recommendations generated from the same analysis

Users have adopted OctaPulse because it delivers measurable cost reduction and accuracy improvements, but the platform lacks a unified view that makes this value continuously visible. Automated inspection catches deformities humans miss and operates 24/7, generating compounding savings over time. Without persistent visibility into these gains, the business case for continued investment becomes abstract.

OctaPulse integrates phenotypic measurements with genetic and environmental data to enable selective breeding decisions, but current capabilities appear to stop at measurement rather than extending into actionable breeding recommendations. The platform captures unprecedented morphometric data at scale and continuously improves sorting criteria through machine learning, creating a foundation for predictive breeding guidance.

OctaPulse has strong early validation through Y Combinator, a $70,000 climate award, and partnerships with NVIDIA, Carnegie Mellon, and Microsoft. Media coverage spans six industry publications. Yet this institutional credibility needs translation into peer validation that resonates with farm operators evaluating adoption.

OctaPulse positions itself at the intersection of automation and ocean health stewardship, emphasizing sustainable food systems and environmental impact. Fish farming produces 0.49% of global greenhouse gas emissions versus 14.5% from meat and dairy, and aquaculture addresses overfishing where 37.7% of stocks are depleted. However, this environmental advantage is not surfaced in actionable reporting for customers.

The platform includes real-time health monitoring and predictive analytics to prevent disease outbreaks, but the evidence suggests these capabilities may be reactive rather than prescriptive. Computer vision analyzes fish condition continuously, and machine learning improves sorting criteria based on operational outcomes. This creates a foundation for predictive intervention.

OctaPulse delivers capabilities competitors are not offering at scale, including real-time phenotyping, autonomous delta robot sorting, and precision morphometric measurements with high accuracy. However, potential customers may not fully understand what distinguishes this platform from alternative automation approaches or legacy manual methods.

Insights

Themes and patterns synthesized from customer feedback

OctaPulse explicitly does not sell personal information and provides users with data access, correction, and deletion rights, while collecting usage data (IP, browser, pages visited, device info) for operational optimization. This approach establishes trust with enterprise customers concerned about data governance while enabling continuous platform improvement.

“Usage data collected includes IP address, browser type, pages visited, time on site, referring websites, and device/OS information”

OctaPulse positions itself at the intersection of cutting-edge automation and ocean health stewardship, with a mission to build scalable infrastructure for sustainable aquaculture. This strategic framing aligns with growing customer interest in environmental impact and establishes differentiation beyond pure automation metrics.

“Company mission is building infrastructure for sustainable aquaculture at scale through advanced technology”

OctaPulse maintains ownership of software, algorithms, and proprietary technology with broad IP protections and reserves non-exclusive licensing rights to user submissions. These protections help preserve the company's technical differentiation and defensibility of its automation capabilities.

“Company claims ownership of software, algorithms, and technology with IP protection across copyright, trademark, patent, and trade secret laws”

OctaPulse supports multiple production environments (net pens, RAS, ponds, flow-through systems) and offers configurable robotic parameters for different fish species and farm-specific breeding goals. This flexibility broadens addressable market and reduces implementation barriers for diverse customer types.

“OctaPulse supports marine and freshwater finfish across all production environments including net pens, RAS, ponds, and flow-through systems”

Typical deployment takes 4-6 weeks from initial assessment to full installation with comprehensive training, reducing customer time-to-value and supporting adoption velocity. This speed of implementation directly influences how quickly users can realize ROI and establish engagement with the platform.

“Typical implementation takes 4-6 weeks from initial assessment to full deployment with comprehensive training”

Leadership combines deep aquaculture industry relationships (CEO) with world-class AI and robotics expertise (CTO from Nvidia, Tesla, Toyota, ASML). This composition builds confidence in both market understanding and execution capability across the core technology stack.

“Leadership team combines marine science expertise (CEO with aquaculture industry relationships) and advanced technical expertise (CTO from Nvidia, Tesla, Toyota, ASML in AI/robotics)”

OctaPulse has achieved significant validation: $70,000 Seafood Industry Climate Award, Y Combinator Winter 2025 acceptance, coverage in six major industry publications, and partnerships with NVIDIA, Carnegie Mellon, and Microsoft. This positions the company as a credible innovator in the aquaculture automation space.

“Company is backed by Y Combinator (W25 batch) and trusted by major technology and research partners including NVIDIA, Carnegie Mellon, and Microsoft”

OctaPulse's platform integrates phenotypic measurements, genetic data, and environmental factors to enable data-driven breeding decisions that optimize growth rate, disease resistance, and product quality. This capability drives customer ROI and long-term farm productivity improvements.

“Integration of genotypic and environmental data with phenotypic measurements to improve selective breeding decisions”

Terms of Service specify 'AS IS' availability with no uptime guarantees and reserve immediate termination rights without notice. This contrasts with enterprise customers requiring production-critical systems and represents a friction point that could impact user retention.

“Services provided on 'AS IS' and 'AS AVAILABLE' basis with no warranties for uninterrupted, secure, or error-free operation”

OctaPulse provides 24/7 technical support, regular software updates, continuous system optimization, and quarterly performance reviews to ensure sustained customer value. This support model directly supports the user engagement and retention metric by reducing operational friction and demonstrating ongoing commitment.

“24/7 technical support, regular software updates, continuous system optimization, and quarterly performance reviews included in standard service package”

The system delivers measurable cost reduction through automation and improves computer vision phenotyping accuracy rates, directly translating to tangible ROI. These quantifiable benefits are critical to sustaining user engagement and retention by proving concrete business value.

“Cost reduction achieved through OctaPulse automation”

OctaPulse's integrated computer vision, robotics, and AI systems deliver real-time phenotyping, precision morphometric measurements, and autonomous delta robot-based sorting at scale—capabilities competitors are not offering. This technical differentiation directly enables the core value proposition of 24/7 automated monitoring and intelligent sorting that surpasses manual inspection.

“OctaPulse combines computer vision, robotics, and data science for precision phenotyping and selective breeding in aquaculture”

Aquaculture produces over 100 million tons annually and is the fastest-growing food sector, yet remains one of the least automated in food production. Fundamental demand drivers—70% more food needed by 2050, declining arable land, and fish's 4-6x feed efficiency over beef—create urgent need for scalable automation solutions.

“Fish farming produces only 0.49% of global GHG emissions vs 14.5% from meat and dairy”

Current aquaculture operations rely on slow, inconsistent manual inspection processes that cannot scale with growing sustainable protein demand, creating operational inefficiency and quality control gaps. This pain point directly motivates adoption of automated alternatives.

“Manual inspection processes in aquaculture are slow, inconsistent, and unable to keep pace with growing demand for sustainable protein”

Run this analysis on your own data

Upload feedback, interviews, or metrics. Get results like these in under 60 seconds.