What Jeevy Fabrication users actually want

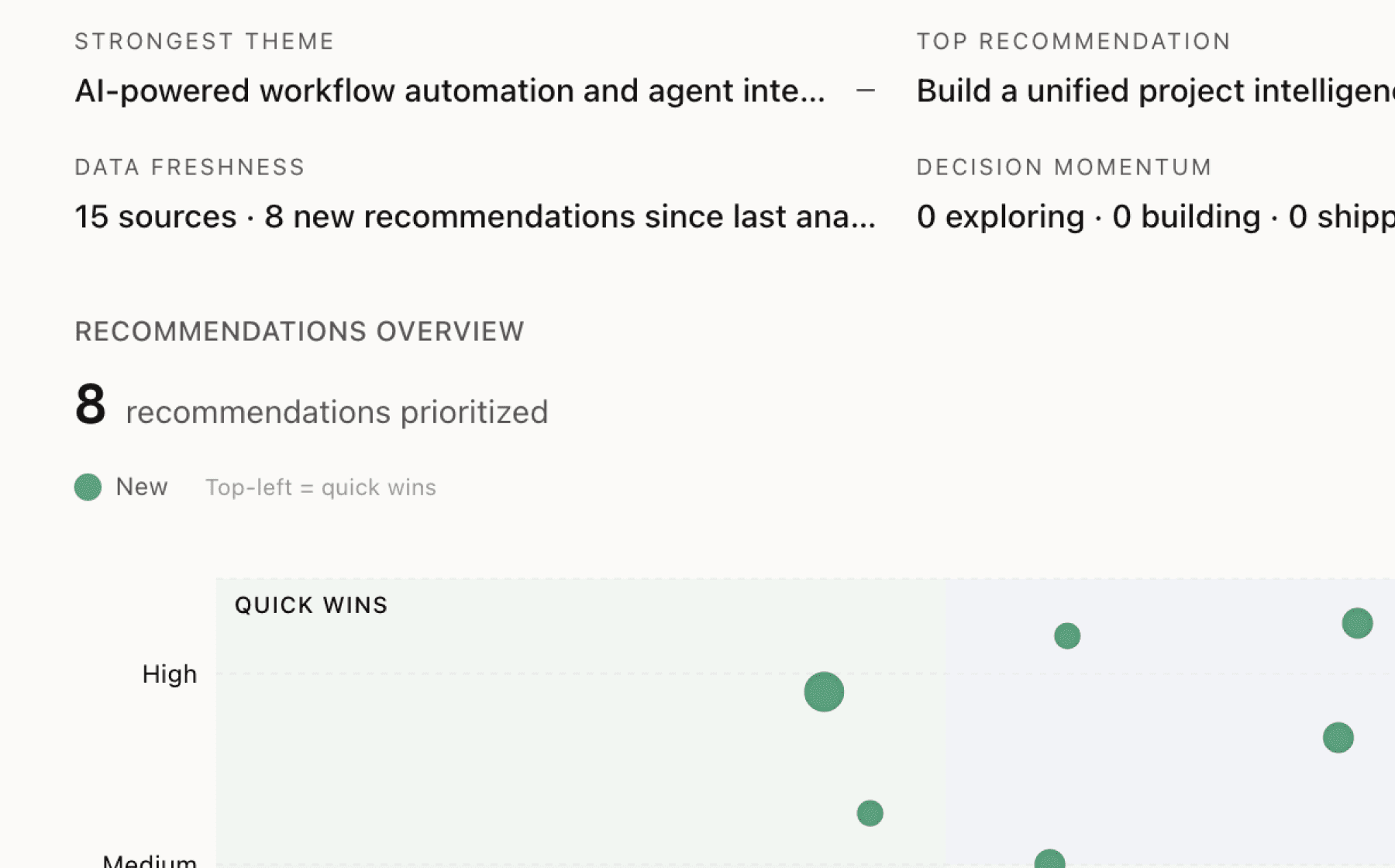

Mimir analyzed 13 public sources — app reviews, Reddit threads, forum posts — and surfaced 9 patterns with 6 actionable recommendations.

This is a preview. Mimir does this with your customer interviews, support tickets, and analytics in under 60 seconds.

Top recommendation

AI-generated, ranked by impact and evidence strength

Build a digital client portal that translates subjective quality expectations into trackable fabrication specifications

High impact · Large effort

Rationale

Jeevy Fabrication defines quality as 'the provision of precisely what the client desires' rather than adherence to standard specifications. While this client-centric philosophy builds strong relationships with aerospace partners like Lockheed Martin and SpaceX, it creates operational friction when scaling or automating workflows. A digital portal that captures client requirements, translates them into measurable fabrication parameters, and tracks delivery against those expectations would preserve the relationship-focused approach while enabling data-driven quality assurance.

This recommendation addresses a fundamental tension between relationship-driven business practices and scalable operations. The company's diverse service portfolio spanning aerospace assemblies, tooling, and field fabrication means quality expectations vary dramatically across projects. A portal that standardizes the intake process while respecting project-specific nuances would reduce miscommunication, improve on-time delivery, and create a foundation for predictive scheduling.

The impact is high because this bridges Jeevy's current strength (trusted aerospace relationships) with operational scalability. It supports the primary metric of user engagement by giving product managers and engineering leads visibility into project requirements and quality benchmarks across the entire portfolio.

Projected impact

The full product behind this analysis

Mimir doesn't just analyze — it's a complete product management workflow from feedback to shipped feature.

Evidence-backed insights

Every insight traces back to real customer signals. No hunches, no guesses.

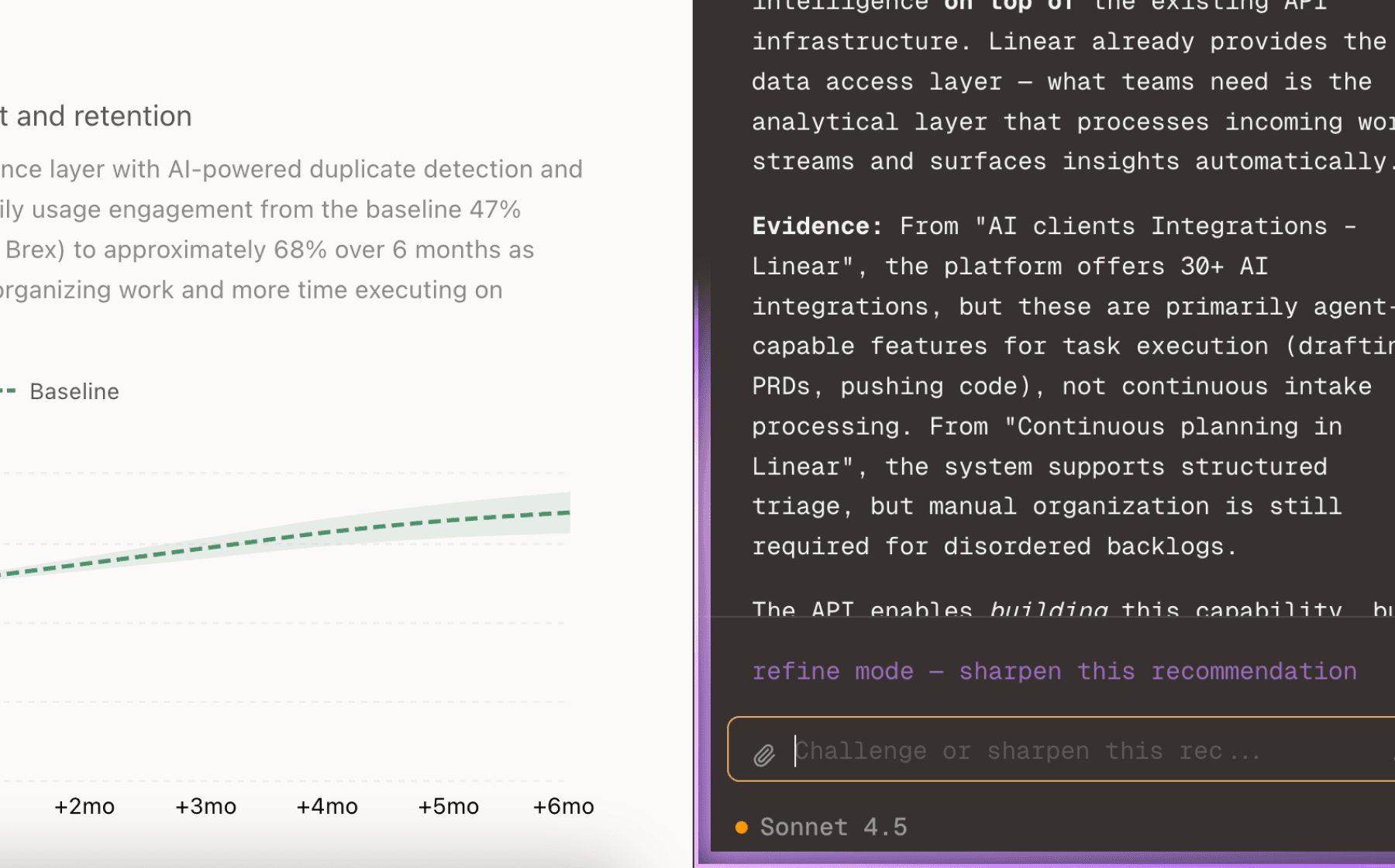

Chat with your data

Ask follow-up questions, refine recommendations, and capture business context through natural conversation.

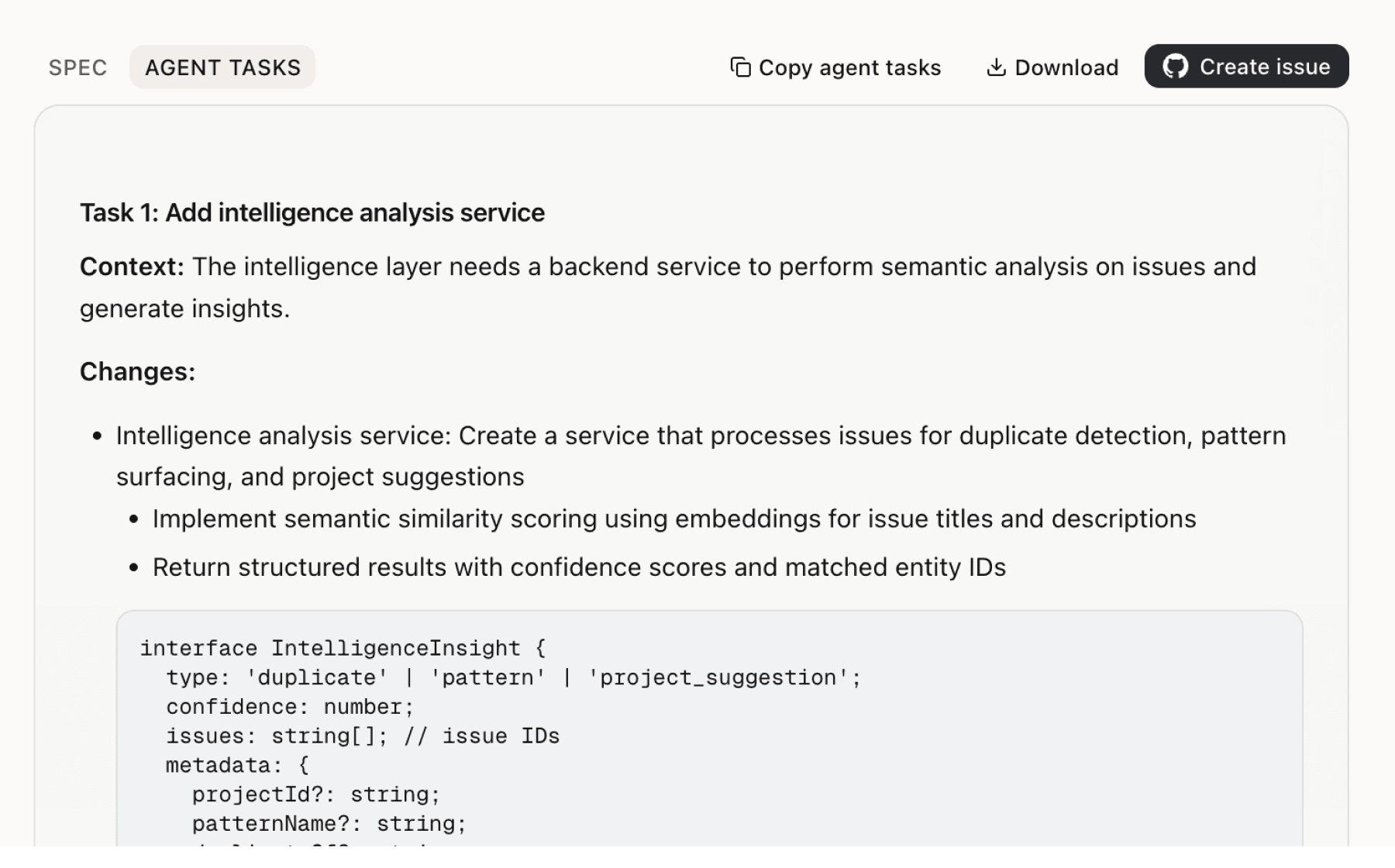

Specs your agents can ship

Go from insight to implementation spec to code-ready tasks in one click.

This analysis used public data only. Imagine what Mimir finds with your customer interviews and product analytics.

Try with your dataMore recommendations

5 additional recommendations generated from the same analysis

With 20 certified welders supporting projects from aerospace tooling to data center steel fabrication, certification matching represents a daily operational constraint. A dashboard that tracks welder certifications, current assignments, and project requirements would improve scheduling efficiency and reduce bottlenecks when specialized certifications are needed for aerospace or defense contracts.

Jeevy offers end-to-end service from in-house fabrication through on-site installation, creating multiple handoff points where delays compound. A predictive logistics tool that models the complete workflow—fabrication completion, painting schedules, delivery windows, and installation coordination—would reduce customer wait times and improve resource utilization across the 55-acre facility.

Jeevy's environmental policy prioritizes source reduction and elimination as the primary waste management strategy, with hazardous waste designed to be recyclable or returnable to suppliers. A tracking system that measures material waste by project type and identifies reduction opportunities would align operational practice with stated environmental commitments and reveal cost savings in material procurement.

Safety is positioned as paramount across all organizational levels, critical for aerospace and defense contracting. A predictive model that identifies high-risk combinations of project characteristics, team experience, and environmental factors would enable proactive intervention before incidents occur, protecting both workers and the company's reputation with tier-one aerospace contractors like Lockheed Martin and SpaceX.

Jeevy maintains multi-year contracts with Lockheed Martin and a trusted relationship with SpaceX, representing critical revenue stability. A dashboard that tracks on-time delivery, quality acceptance rates, and relationship health metrics for these tier-one customers would provide early warning of performance degradation and inform resource allocation decisions to protect high-value contracts.

Insights

Themes and patterns synthesized from customer feedback

Jeevy Fabrication implements an 8-principle environmental policy prioritizing source reduction and elimination as the primary approach, with recycling and sustainable practices as secondary strategies. The company manages hazardous waste to be recyclable or returnable to suppliers, reflecting commitment to circular economy principles in manufacturing.

“Jeevy Fabrication has a structured environmental policy with 8 core principles focused on waste reduction, recycling, and sustainable practices”

Jeevy Fabrication offers complete project solutions including in-house fabrication, painting, delivery, and on-site installation at customer job sites, supported by an interior fabrication facility and field team collaboration. This vertical integration reduces coordination friction and enables greater control over quality and scheduling.

“Company offers end-to-end solutions including fabrication in-house, painting, delivery, and installation at customer job sites”

Jeevy Fabrication operates a 55-acre facility with 5 buildings located 5 miles from Kennedy Space Center in Texas, strategically positioned between Cleburne and Grandview. This location proximity to major aerospace customers and HUB designation may provide logistical and contracting advantages in the aerospace and defense sector.

“Jeevy Fabrication operates a 55-acre facility with 5 buildings and employs 20 certified welders with diverse welding certifications”

Jeevy Fabrication emphasizes trust-building with employees, clients, contractors, and regulatory agencies through ethical conduct and integrity as foundational values. This stakeholder-centric approach reflects a relationship-based business model particularly suited to aerospace and defense environments where trust and compliance are operational imperatives.

“Company emphasizes trust-building with employees, clients, contractors, and regulatory agencies through ethical conduct and integrity”

Jeevy Fabrication operates across data center engineering, steel manufacturing, field fabrication, tooling design, custom engineering, aerospace assemblies, and piping—offering both design/engineering and execution phases. This broad service coverage creates multiple revenue streams and positions the company as a comprehensive solution provider rather than a single-capability vendor.

“Jeevy Fabrication operates across multiple service categories including data center engineering, steel manufacturing, field fabrication, tooling design, custom engineering, and aerospace assemblies”

Jeevy Fabrication defines quality as "the provision of precisely what the client desires" with dedicated QA policies focused on achieving client goals, rather than meeting standard specifications. This client-centric quality philosophy may differentiate the company in relationship-driven industries like aerospace but could create ambiguity in metrics-based product automation systems.

“Quality is defined as the provision of precisely what the client desires”

Jeevy Fabrication employs 20 certified welders with diverse welding certifications and experienced inspection personnel, indicating demonstrated capability in aerospace-grade fabrication. This workforce investment demonstrates commitment to quality standards and capability to execute complex weld fabrication projects.

“Jeevy Fabrication employs 20 certified welders”

Safety is treated with utmost seriousness across all organizational levels at Jeevy Fabrication and is supported by dedicated safety pages and formal policies. This foundational safety culture is essential for aerospace and defense contracting and reflects regulatory and operational requirements for weld fabrication environments.

“Safety is positioned as a paramount organizational priority across all levels, treated with utmost seriousness”

Jeevy Fabrication maintains multi-year contracts with Lockheed Martin for tooling maintenance and a trusted relationship with SpaceX, positioning the company as a reliable partner in high-stakes aerospace and defense environments. These long-term commitments represent significant revenue stability and validation of quality and capability standards required by tier-one aerospace contractors.

“Holds multi-year contracts with Lockheed for tooling maintenance and trusted relationship with SpaceX”

Run this analysis on your own data

Upload feedback, interviews, or metrics. Get results like these in under 60 seconds.