What pollinate users actually want

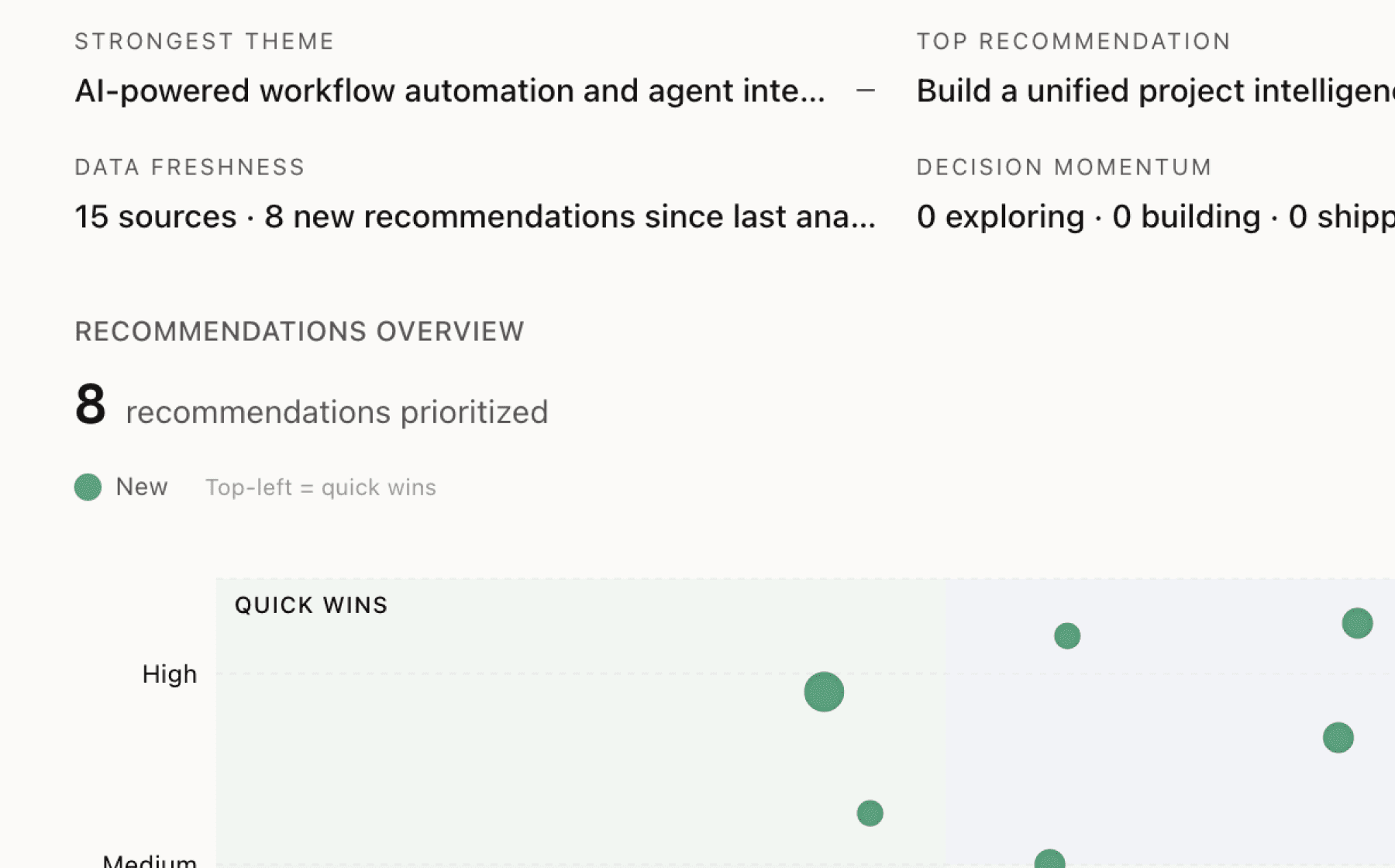

Mimir analyzed 1 public source — app reviews, Reddit threads, forum posts — and surfaced 6 patterns with 5 actionable recommendations.

This is a preview. Mimir does this with your customer interviews, support tickets, and analytics in under 60 seconds.

Top recommendation

AI-generated, ranked by impact and evidence strength

Build a unified supply chain control center that surfaces critical disruptions before they stop production

High impact · Large effort

Rationale

Three sources confirm that teams discover parts shortages too late to prevent line stoppages, and the current reactive posture wastes resources on fire drills. A single dashboard aggregating inbound logistics, parts availability, and risk signals would shift teams from reactive to proactive management. This directly addresses the company's core value proposition of reducing supply chain overhead and bottlenecks.

The control center should prioritize early warning systems over comprehensive coverage. Focus on the critical path items that stop lines—parts under $1 that cause disproportionate disruption, PCB lead times against commits, and inbound shipment delays. Real-time visibility enables intervention hours or days before a crisis, protecting the primary metric of customer retention by preventing the production stoppages that erode trust.

This recommendation synthesizes four distinct pain points into one coherent product experience: late shortage visibility, opaque inbound logistics, PCB tracking gaps, and reactive management posture. Rather than building four separate trackers, create a unified interface where procurement teams see what matters most right now.

Projected impact

The full product behind this analysis

Mimir doesn't just analyze — it's a complete product management workflow from feedback to shipped feature.

Evidence-backed insights

Every insight traces back to real customer signals. No hunches, no guesses.

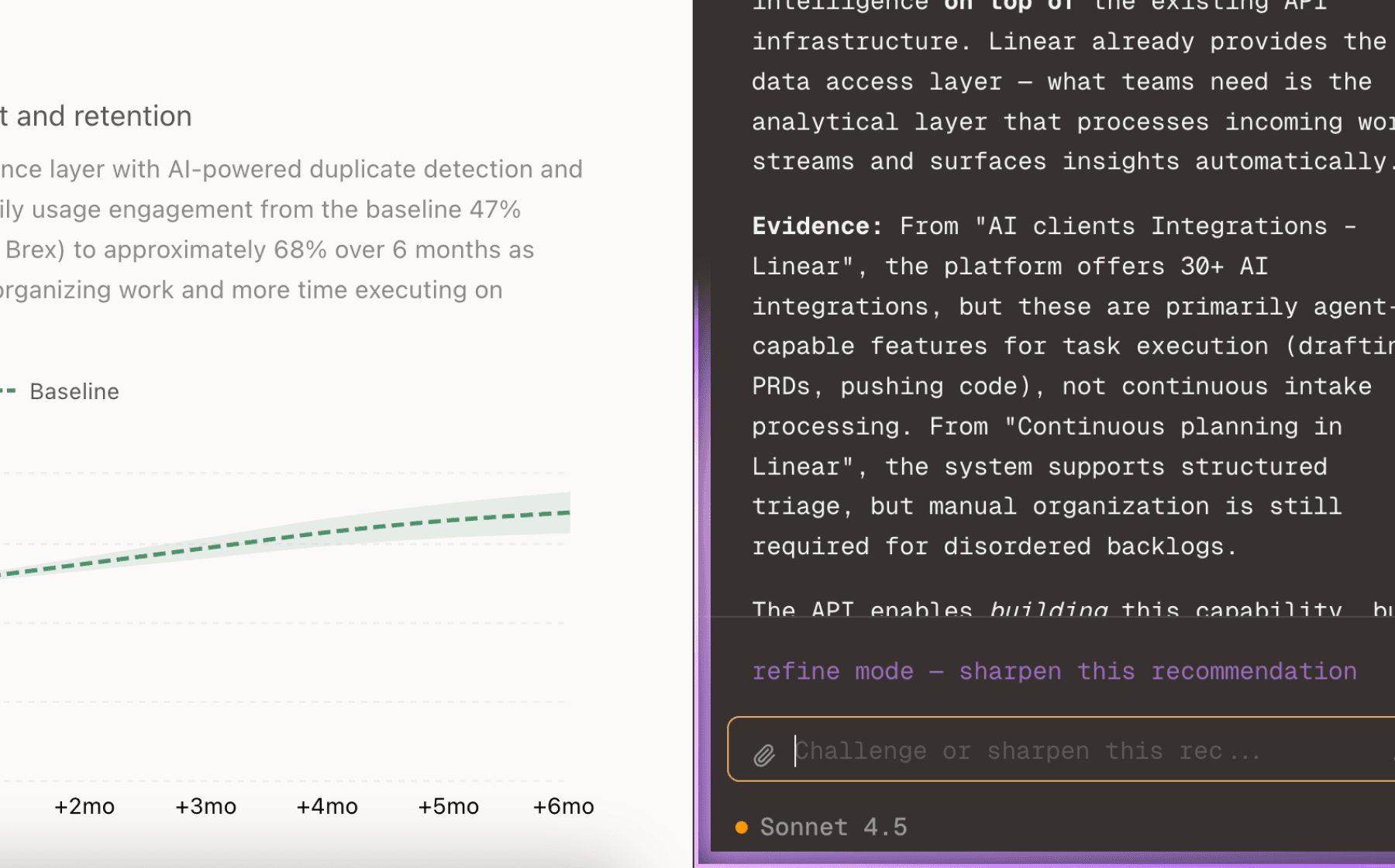

Chat with your data

Ask follow-up questions, refine recommendations, and capture business context through natural conversation.

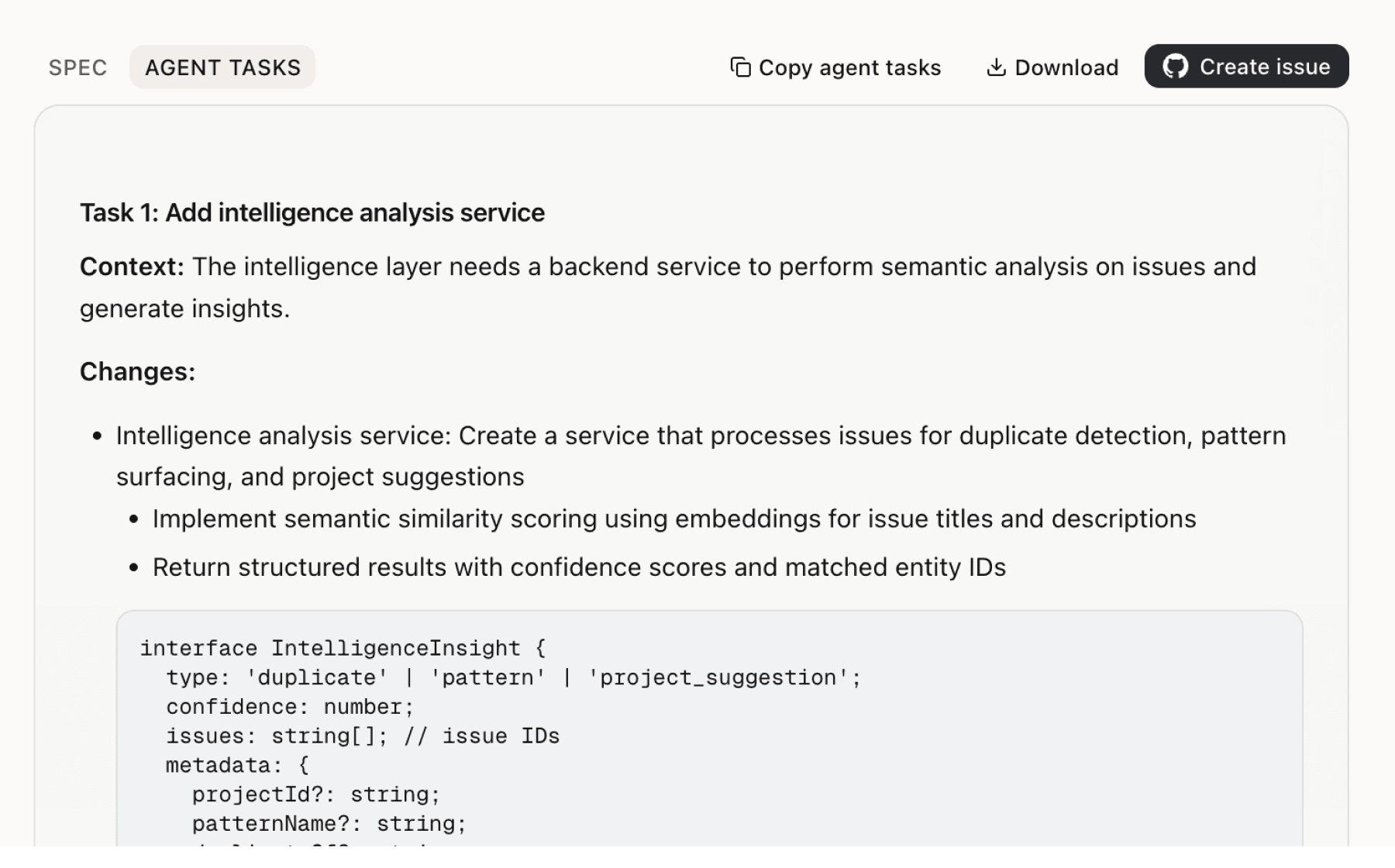

Specs your agents can ship

Go from insight to implementation spec to code-ready tasks in one click.

This analysis used public data only. Imagine what Mimir finds with your customer interviews and product analytics.

Try with your dataMore recommendations

4 additional recommendations generated from the same analysis

Engineering change orders force procurement teams to manually rewrite requests and purchase orders, creating coordination bottlenecks that delay production updates. Two sources identify this as a high-friction process ripe for automation. Since Polinate already integrates with ERP systems, extending that integration to capture ECO events and automatically generate updated vendor communications is technically feasible.

One source reports that losing a single person can eliminate half the supply chain, exposing how fragile operations become when critical knowledge lives only in people's heads. This risk directly threatens customer retention and business continuity. While Polinate focuses on software automation, addressing this vulnerability requires capturing institutional knowledge and codifying workflows before they walk out the door.

Procurement teams currently patch together disconnected tools to search compliant vendors, match invoices, and close reconciliation loops. One source identifies this as forcing workarounds that slow sourcing cycles. This gap represents a natural extension of Polinate's ERP integration—the data for vendor compliance, purchase orders, and invoices already flows through connected systems.

Three sources confirm that teams currently manage operations in spreadsheets, creating fragility and inefficiency. However, these spreadsheets exist because they offer flexibility and familiarity that rigid ERP systems don't provide. Rather than forcing teams to abandon their existing tools, create a migration path that keeps spreadsheets as the interface while Polinate handles automation and integration underneath.

Insights

Themes and patterns synthesized from customer feedback

When ECOs occur, procurement teams manually rewrite RFQs and POs instead of propagating changes automatically to vendors, creating delays and coordination bottlenecks. Automating this handoff could eliminate a high-friction process.

“Instant ECO propagation to purchasing and vendors without manual rewrites of RFQs and POs”

Procurement teams lack a unified system to search compliant vendors, match invoices, and close reconciliation loops, requiring manual processes that slow sourcing cycles. Integrated vendor search with 3-way matching would streamline this core workflow.

“Integrated vendor search with 3-way invoice matching to source compliant parts and close reconciliation loops”

Electronics manufacturers need real-time tracking of PCB procurement against committed lead times and risk signals to avoid line stoppages. A dedicated tracking system would enable proactive supplier and schedule management.

“Real-time PCB procurement management tracking parts against lead times, commits, and risk signals”

Procurement and operations teams lack visibility into actual shipment arrivals, delays, and kit-ready status, preventing them from planning or reacting before stock reaches the production line. A live receiving tracker would enable earlier intervention.

“Live inbound and receiving tracker showing actual arrivals, delays, and kit-ready status”

Teams act as manual integration layers between spreadsheets and disconnected systems, duplicating work and creating single points of failure when key personnel leave. This fragmentation makes the supply chain inherently inefficient and vulnerable to disruption.

“Managing supply chain operations in spreadsheets causes system fragility and inefficiency”

Procurement teams lack real-time visibility into parts availability and logistics, discovering shortages too late to prevent production line stoppages and cascading delays. This reactive posture wastes resources on crisis management rather than proactive planning.

“Late visibility into parts shortages causes production line stoppages and cascading delays”

Run this analysis on your own data

Upload feedback, interviews, or metrics. Get results like these in under 60 seconds.